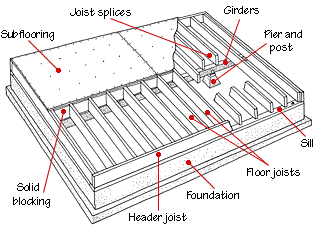

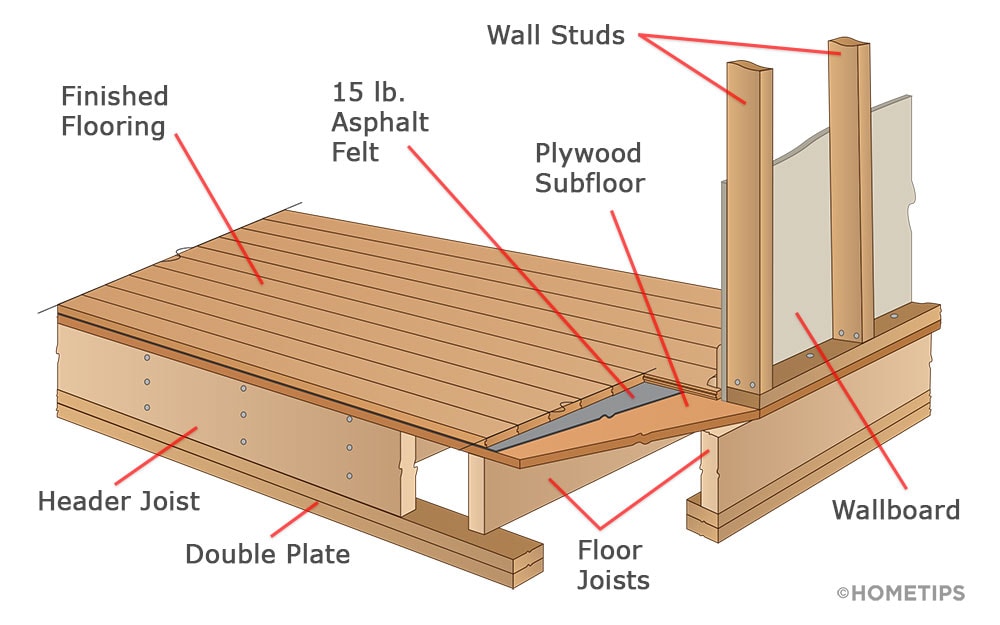

This illustrated guide has diagrams that show how a typical wood-frame floor is built, from floor joists to subfloor and the sill plate.

What Are Floor Joists?

What Is a Subfloor?

What Is a Sill Plate?

Though some floors of houses are built on a concrete slab flat on the ground, most residential floors are raised above the ground. Raised floors are more resilient under foot and provide access for heating equipment, insulation, plumbing, wiring, and other mechanical equipment.

A raised floor is constructed with a wooden framework that bridges from one exterior wall to another. This framework may or may not be supported intermediately by girders, beams, or walls.

On upper levels of a house, the underside of the floor framing serves a dual purpose. It acts as the structural support for the floor above while also providing the backing for the ceiling materials below. Ceilings, in essence, are constructed similarly to floors but typically utilize lighter materials due to their lower load-bearing requirements.

What Are Floor Joists?

A floor’s framework is made up mostly of wooden joists (thin wooden beams) that run parallel to one another at regular intervals. Floor joists are typically 2 by 8s, 2 by 10s, or 2 by 12s; ceiling joists are usually 2 by 6s or sometimes 2 by 4s if it is an older home. Some newer homes have manufactured, I-beam–shaped joists.

Floor joists, spaced on regular intervals, span the areas between supports such as walls, foundations, girders, and beams. Normal spacing is 16 inches “on center” (from center to center), though some floors may have joists on 12-inch or 24-inch centers. Joist sizing and spacing are determined by building codes, which are based on engineering requirements. Joist headers run perpendicular to the joists, capping their ends.

Joists are spliced over beams or other supports. They may be butted end-to-end and connected with plywood gusset plates or lapped. Solid blocking or metal bridging prevents joists from twisting and helps distribute loads evenly.

Wherever an opening occurs, such as for a staircase, joists are doubled up at the perimeter and capped with perpendicular headers.

What Is a Subfloor?

Subflooring plays a vital role in the construction of a raised floor. It acts as a base for the final finish flooring, such as hardwood, tile, or carpet, and also serves as a working platform during the construction process.

Subflooring can be constructed in a few different ways:

- Boards: Laid either perpendicular or diagonally across the joists.

- Plywood or Panel Products: Typically laid perpendicular to the joists.

Plywood Subflooring: A Popular Choice

Plywood subflooring is a common option due to its strength and stability. The panels are laid in a staggered pattern, with the ends and edges butted tightly together. They are then securely fastened to the floor joists using nails, and often, construction adhesive for added strength and stability.

Subfloor Thickness and Stiffness for Finish Flooring

The thickness and rigidity of your subfloor play a crucial role in determining which finish flooring options are suitable. If your house is built on a concrete slab, you have a solid base that can accommodate most flooring types. However, for homes with a plywood or board subfloor, the type and thickness of the subfloor material determine your limitations.

Flexibility vs. Rigidity

A slightly flexible or “springy” subfloor is not ideal for rigid materials like ceramic tile or stone. The movement of the subfloor can cause the grout or even the tiles themselves to crack over time. In such cases, it’s important to choose a more flexible finish flooring option, such as hardwood, vinyl, or laminate, or to reinforce the subfloor to improve its rigidity before installing rigid flooring.

Always Check Recommendations

Before choosing your finish flooring, it’s essential to check the manufacturer’s recommendations for subfloor requirements. This will help ensure a successful installation and a beautiful, long-lasting floor.

What Is a Sill Plate?

At the foundation level, floor joists rest directly on a sill that is treated with preservative so that contact with the foundation will not promote termites or rot. Their exact construction and connection with the wall studs depend on the method of framing that is utilized.

Featured Resource: Get a Pre-Screened Local House Framing Contractor

Don Vandervort writes or edits every article at HomeTips. Don has:

Don Vandervort writes or edits every article at HomeTips. Don has: