Everything you need to know about carpeting types, cuts, manufacturing processes, and installation

Types of Carpet Fibers

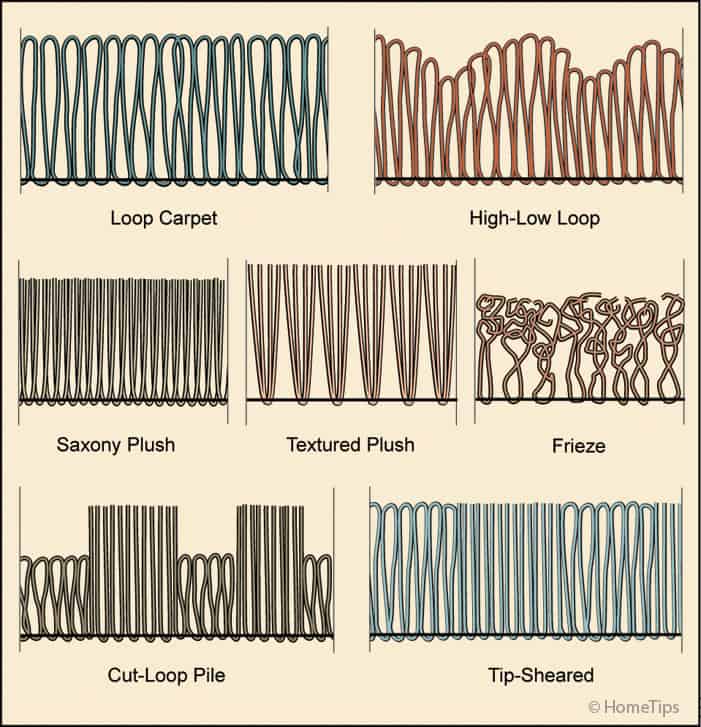

Carpet Loops & Cuts

Carpet Cushion & Padding

Few remodeling milestones are as gratifying as the day wall-to-wall carpeting is rolled out and stretched into place. Within a few hours, a bedroom awakens with color and style, a living room radiates warmth and luxury, or a family room grows cozy and comfortable.

According to the Carpet and Rug Institute (CRI), more than six out of ten American homeowners prefer wall-to-wall carpeting over other flooring for those spaces. To meet that level of demand, over 2 billion square yards of carpet will be produced this year-enough to run a 12-foot-wide swath around the Earth’s equator twelve times.

Why the popularity? Carpeting’s benefits are obvious: It is comfortable, sound-deadening, warm, relatively affordable, quick to install, available in thousands of colors and styles, and can unify a home’s interior.

In the industry, wall-to-wall carpet is known as “broadloom carpet.” Carpets and rugs over 6 by 9 feet qualify as broadloom, a reference to the looms once used to manufacture wider-than-normal rugs. Today, most broadloom carpet is sold in 12-foot widths.

Carpets today differ in how they are made. More than 90% of today’s carpet is tufted by machines that are like huge sewing machines. Fitted with several hundred needles, these machines operate at extremely high speeds to stitch rows of face yarn tufts to a synthetic fabric, called the “primary backing.”

Unless yarns are pre-colored, they’re dyed. Then the primary backing is coated with latex adhesive and reinforced with a secondary backing, normally made of polypropylene. Some carpets, notably commercial varieties, may have a resilient cushion attached to this backing.

Broadloom carpet is produced by other methods, too. A small percentage-less than 3%-is made on a loom that weaves face and backing yarns together. Although woven carpets have no actual backing fabric, a coating of latex is applied to the underside. Some commercial carpet tiles or modules (normally 18 by 18 inches) are made through a fusion-bonding process where yarn fibers are injected into an adhesive-coated backing.

Carpeting is applied over padding most of the time. Dense (not necessarily thick) padding prolongs carpet life, reduces noise, and cushions the floor.

Before a carpet is laid, tackless stripping, called “tackstrips” for short, is nailed around the perimeter of the floor.

These thin strips of wood have short tack points that stick upward to grab onto the carpet’s backing. One edge of the carpet is hooked onto the protruding points of the stripping, and then the carpeting is stretched tight, hooked onto the tackless strips at the opposite wall, and then trimmed. Seams between widths are joined from behind with fiberglass adhesive seaming tape or a thermal plastic seam tape that is applied with a special iron.

Carpet can be applied over almost any subfloor or existing flooring-except for old carpet. A thick pile will hide irregularities in subflooring in a way that most other flooring won’t.

Types of Carpet Fibers

The fibers used for a carpet’s face yarn dramatically affect its appearance and performance. Here is a closer look at the carpet fibers used today:

Nylon

Two-thirds of carpet fibers are nylon. Nylon fibers are wear, soil, and mildew resistant, survive the crushing weight of furniture, and hold up well in heavily trafficked areas.

Nylon is available in brilliant colors, and solution-dyed varieties are colorfast. Nylon carpets tend to cost from about $8 to $25 per square yard. At rock-bottom, they run as low as $5; at the high end, you can pay $70 per square yard or more.

Olefin

Also known as polypropylene, olefin fibers represent about 30% of the carpet market. Although olefin began as an outdoor carpet fiber thanks to its resistance to moisture and mildew, new advances in its look and feel have made it popular for the house. It is easy to clean, strong, and resists stains, wear, and static electricity.

Olefin fibers are used primarily in multilevel loops, such as Berbers, and in low-profile commercial cut piles. Color is added before the material is turned into fiber, making olefin colorfast. Some carpet tiles made of olefin are felt-like in texture; for these, polypropylene fibers are needle-punched into a mesh core. Olefin carpet is comparable in price to nylon; although the fiber is less expensive, more processes are involved in its manufacture.

Polyester

If you like a luxurious, soft, thick-cut pile, polyester may be your best bet. Polyester fibers, known for their soft “hand,” have plenty of body, resist wear, and offer strong color and luster retention. However, they are not as durable as nylon and olefin. Currently, many polyester carpets are made from recycled PET (polyester) from plastic soda bottles and containers. Polyester carpets run about $1 less per square yard than comparable nylon products.

Triexta

Triexta is a relatively new generic subclass of polyester. Invented by DuPont, triexta is permanently stain resistant and extremely durable, resilient, and friendly underfoot. The manufacture of triexta, which utilizes renewable resources, is much greener than the manufacture of other synthetic carpet fibers. Two brands of carpeting manufactured with triexta are DuPont Sorona and Mohawk Smartstrand.

Acrylic

Although you won’t likely find a 100% acrylic carpet, these fibers are blended with other fibers such as wool because they approximate the look and feel of natural wool but are less expensive. Acrylic fibers are resistant to moisture, mildew, and fading.

Wool

The most luxurious fiber is natural wool. It is soft, durable, offers generous bulk, and comes in many colors. From an ecological standpoint, it is a particularly responsible choice because it comes from a sustainable resource. Unfortunately, wool is also considerably more expensive than synthetics. For wool, you’re likely to pay from $40 to $100 per square yard or even more.

Carpet Loops & Cuts

A carpet’s basic qualities depend on its construction—whether the pile is cut, looped, or both cut and looped.

Cut-Pile Carpets

Cut-pile carpets have loops trimmed off so that yarn ends poke upward, creating a luxurious look and feel-clearly one of the reasons they represent 60% of carpets sold. Within the cut-pile family are the highly popular “saxonies.” Saxony plush has densely packed, short, level tufts.

Textured plushes have slightly taller pile and are less dense. “Freize” (free-zay) carpet is a somewhat rare, rugged, nubby style with a dense, low pile and tightly twisted yarns. Another type of cut-pile carpet is the velvet, with short, very tight pile.

A velvet carpet is smooth, level, and uniform with a formal look. When you walk on it, footprints tend to show (the more textured a surface, the less it shows footprints).

A cut-pile carpet’s “hand”—the look, texture, and feel—is a result of the fibers chosen for the yarn and the yarn’s gauge (“denier”) and twist. These elements are critical to performance. The more tightly twisted the yarn, the better the performance, as a rule, because the yarn retains its shape over time. Most cut-pile yarns are heat-set to hold their shape (the same way a hair permanent heat-sets a hairstyle).

Loop Carpets

Loop carpet, the result of tufting, has complete yarn loops that stand upright. Loops tend to wear better than cut-pile carpets because the yarn tips are not exposed. With these, yarn wears on the sides, not the ends, and the twist is automatically maintained.

For a particularly smooth surface, often preferred in commercial installations, you can get a “low-level loop.” For striking patterns or a sculptured look, you can buy a “multi-level loop.” Sculptured carpets have both high and low loops.

High-level loops, such as Berbers, have a nubby texture. In fact, most loop piles are now called Berbers, a term that originated with the rugs made by the Berber tribes of Africa.

Cut & Looped Carpets

Cut-loop pile and tip-sheared carpets combine loops with cut pile. The cut-loop pile has cut ends that are taller than the loops, creating a variety of looks. Conventional types, sometimes called “sculptured” carpets, offer bold patterns and colors. More subtle versions, called “traceries” or “carved Saxonies” merely suggest a pattern.

Carpet Cushion & Padding

Most residential carpet is installed over a separate carpet pad (called “cushion” in the industry) that makes the carpet softer and more resilient underfoot, reduces noise, provides a little thermal insulation, and prolongs carpet life. Don’t make the mistake of installing a quality carpet over the top of a marginal carpet cushion.

Carpet cushion may be made from any of several materials, including various types of natural and synthetic fibers and urethane foam.

A carpet cushion that is too thick over-stresses the carpet backing and is too soft underfoot. The density of the carpet cushion—not its thickness—is the most important factor to consider when choosing a carpet pad. Ask your carpet retailer for a Class 1 cushion for moderate traffic areas and a Class 2 cushion where there will be heavy traffic, such as stairs, hallways, and family rooms.

The Carpet and Rug Institute recommends a maximum thickness of 7/16 inch for a residential carpet cushion. If the

carpet has a lower pile height, such as a Berber or a commercial-like cut pile, the cushion should be even thinner—3/8 inch or less. But it should be firm and resilient.

FHA minimums are 6-pound cushion under standard residential cut pile and 8-pound cushion under a thinner Berber or low pile. Expect to pay about $3 to $3.50 per yard for quality cushion.

Don Vandervort writes or edits every article at HomeTips. Don has:

Don Vandervort writes or edits every article at HomeTips. Don has: