An in-depth buying guide about architectural trim, detailing, millwork, and materials commonly used to create exterior decorative trim pieces.

Composite Trim Materials

Plaster Trim & Detailing

Polyurethane Foam Trim

Wood Trim & Detailing

Architectural Terminology

Have you ever marveled at the intricate gingerbread of a classic San Francisco Victorian, admired a stately Southern Colonial, or enjoyed the hand-wrought detailing of a Craftsman bungalow?

One feature that all outstanding traditional-style homes share is great architectural millwork: the moldings, posts, columns, and other detailing applied to house exteriors.

Greek Revival, Colonial, Georgian, Craftsman—these classic house styles as well as several others rely heavily upon columns as key architectural components. In fact, columns have returned to popularity not only for these traditional homes but also for many newer house styles to add visual interest, extend the façade of the house, and support porches. For more about columns, see Architectural Column Buying Guide.

In this section of HomeTips, you will find helpful information about the types of architectural detailing and columns used on houses.

New architectural detailing, columns, and similar millwork are made from a variety of materials. Here is a closer look at each:

Composite Trim Materials

PrimeTrim exterior and interior trim from Georgia-Pacific is an all-wood composite that is highly resistant to rot and decay and has no knots, finger joints, or defects. It is sold factory-primed on the face and two edges and is said to require re-painting less than traditional wood trim. It is made in 16-foot lengths and may have either a smooth or textured surface.

Plaster Trim & Detailing

Plaster has been used for centuries to create interesting detailing. On building exteriors, it is used for some columns, corbels, wall plaques, and other small details.

One plus for plaster is that it is all-natural; it is made from gypsum and typically reinforced with hemp. But it must be sealed for weather protection.

Plaster Cast Designs, in Shelbyville, Tenn., is one company that sells an extensive line of stock parts by mail order and can custom-cast parts by request.

Polyurethane Foam Trim

New moldings and architectural elements are commonly made from high-density polyurethane foam. Easy to cut and fasten with standard woodworking tools, polyurethane isn’t subject to some problems associated with wood: shrinkage, expansion, warping, splintering, and decay.

Molded detailing is usually factory finished with a UV-inhibiting primer and white acrylic finish. Components may be painted or stained with a non-penetrating stain, and, unlike finishes on wood, finishes on polyurethane tend to last somewhat longer.

Unlike wood moldings that are often combined from several different pieces, these products are one piece, which makes them much more affordable to install than wood.

Many different components are available. The largest manufacturer of these products, Fypon, makes more than 3,500 different styles and sizes. And if you can’t find a stock piece that suits you, you can get it custom-formed to your specifications. NMC Focal Point and Orac Decor also distribute a full line of products throughout the United States.

Typical products made from polyurethane include door surrounds (both complete or with separate pilasters, mantels, and pediments), decorative window headers, raised panels for under windows, decorative scrollwork brackets, gable-end trim, corner trim, shutters, dentil blocks for under soffits, cornice moldings, and more.

Many homeowners install polyurethane moldings themselves, following the manufacturer’s instructions. These materials are cut with conventional woodworking saws (a special miter box is available for large profiles). They’re usually tacked in place with finishing nails, but special adhesives are used for joining moldings that create joints guaranteed not to crack or separate. Small profiles are priced similarly to wood, but larger profiles are more economical because they’re made as a single piece.

For mail-order catalogs or the names of nearby dealers, you can contact the companies directly. Because the offerings are so vast, the best way to check prices is to get a catalog or look online. For example, Orac Decor’s most popular crown moldings range from about $10 per lineal foot to $17 per foot. All are sold in 6 1/2-foot lengths.

Wood Trim & Detailing

Wooden detailing is easy to cut and fasten, durable, and-of importance to restoration purists-authentic. Pine, a softwood, is very commonly used; poplar is a moderately priced hardwood. Other species such as redwood, cedar, and oak are used, too. Although some species, such as redwood and cedar heartwood, have a natural resistance to decay, all wood must be protected from weathering with stain or paint. To guarantee continued protection, this finish must be reapplied every few years.

Wooden gingerbread, newel posts, porch posts, moldings, and similar wooden millwork are made both by small local mills and by large mills that distribute to home improvement centers, lumberyards, and millwork shops, and sell directly online and through mail-order catalogs.

Two such companies that offer products by mail order are Silverton Victorian Millworks and Vintage Wood Works. These companies have many stock components and will produce custom components.

How much does wooden detailing cost? Because the offerings are so varied, even ballpark prices are almost impossible to give. Silverton’s popular Colorado handrail, which is 2 inches by 2 3/4 inches, runs about $4.50 per lineal foot in hemlock and $7.50 per lineal foot in oak. The best way to see the selections and pinpoint prices is to look at manufacturer sites online or request a catalog.

In general, quality wood is a scarce and expensive resource-and you pay for it accordingly. Wood meant to be painted is considerably less expensive than material meant to be finished naturally or stained with a transparent finish. When choosing wood, you must also consider the fact that many types of moldings are actually built up on site from several molding profiles; both labor and material costs can escalate with the degree of complexity.

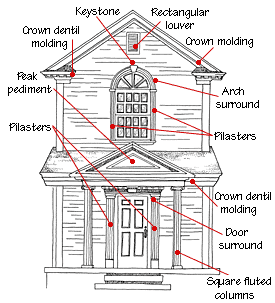

Architectural Millwork Terminology

Here are some of the basic terms that are used for describing architectural millwork:

Arch surround. Half-round or elliptical trim mounted above a door or window.

Bracket. Filigree or ornamental blocks between a vertical support and horizontal member. Brackets usually provide crossbracing or support between a post and beam or beam and cornice.

Capital. The decorative top of a column or pilaster.

Corbel. A short block or bracket projecting from a wall, often meant to provide support for a horizontal member. See What Is a Corbel? BELOW.

Cornice. A projection at the top of a wall, under a roof’s eaves.

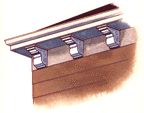

Dentil blocks. Blocks attached to a wall in a toothed pattern.

Dentil molding. A toothed moulding attached to a wall. See BELOW for more.

Gable decoration. Triangular-shaped filigree or panel fit into the rake end of a gable roof.

Header or head. A horizontal projection over the top of a window or doorway.

Keystone. An angular block centered over a door or window in a header or mantle.

Louvers. Slatted panels of various shapes mounted in the upper portion of a gable wall to provide attic ventilation.

Mantel. A horizontal projection over the top of a doorway.

Moldings. A variety of trim pieces, usually sold in lengths.

Pediment. A peaked, rounded, or other decorative panel directly above a doorway.

Pilasters. Decorative vertical columns attached to the wall or frame at either side of a doorway.

Quoins. Rectangular blocks that extend up the corner of a building.

Shutters. Operable or decorative window covers mounted to each side of a window.

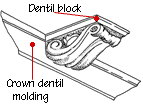

Dentil Molding

Dentil molding, a small rectangular block that, when repeated, resembles a row of spaced teeth, is applied to houses as a type of decorative trim. From the Latin word ”dent,” meaning tooth, dentil moulding first appeared in 16th-century France.

Common in Corinthian architecture, this type of fanciful millwork is typically nailed along the fascia or beneath the cornice of a traditional home, or it may be installed as a type of crown moulding around the perimeter of a room’s ceiling.

In the past, dentil molding was tediously made, piece by piece, from wood or plaster. Today, it is still made that way, but you can take a short cut to achieve the same look. You can buy lengths of single-piece polyurethane foam or vinyl molding, which are more affordable and less prone to decay, shrinkage, peeling, and other problems common to built-up millwork.

What Is a Corbel?

A corbel is an architectural projection or bracket-like support that steps out from a wall to hold a beam or other weight, although some corbels are purely decorative.

A corbel, sometimes called corbelling, may be bricks or stones set out from the wall’s face, or it may be a short, sometimes carved, piece of wood. Corbel is also used as a verb: To corbel out means to build a corbel. The Old French word ”corbel stems” from the Latin corvus, for raven, possibly referring to early gargoyles.

Corbel appeared as an architectural term in the 15th century, indicating a projection from a wall designed to support a weight. Classic French architects were fairly specific about a corbel’s makeup, specifying that a corbel’s sides were perpendicular to the wall and it projected further than its height.

In England, corbel was strictly a technical architectural term until given mystique by Sir Walter Scott when, in his 1805 novel, “Lay of the Last Minstrel,” he wrote: “The corbels were carved grotesque and grim.”

The term “architectural millwork” encompasses a range of materials and products. Also known as “architectural trim,” “architectural ornamentation,” “detailing,” “carpenter art,” or simply “trim,” this refers to the shutters that flank windows, pediments and pilasters that surround doors, dentil and crown moldings, columns, and other elements that add interest and anchor a house’s architecture in the vernacular of a given period and style.

Much millwork serves a functional role, too. Moldings hide the transitions between differing materials, and columns provide support, for example. Structural columns are made from wood, extruded aluminum, or fiberglass composites. Non-structural, decorative columns, made from polymers, are hollow in the center to allow for a wood or metal post.

If you own an older traditional house-or even intend to build a traditional-style home-it pays to be familiar with decorative millwork. The trim of many older homes often has been removed or, where it has not been removed, it’s in shoddy condition, because millwork is particularly vulnerable to the abuses of harsh weather. Some vinyl siding manufacturers offer a range of decorative classic millwork that coordinates with their systems. These include door and window surrounds, shutters, corner posts, dentil moldings, and more.

The traditional material for architectural detailing is wood-typically pine, fir, redwood, or cedar. Ornate patterns of molding and millwork are made up by combining a variety of simpler wood molding profiles.

Don Vandervort writes or edits every article at HomeTips. Don has:

Don Vandervort writes or edits every article at HomeTips. Don has: