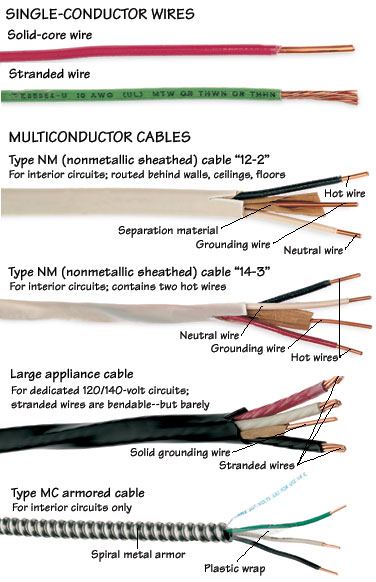

An illustrated explanation of the differences between single-conductor wires and multiconductor cables

In older homes, the electrical system is likely made up of single conductor wires. Today, however, much of electrical wiring is done with multiconductor cables because of their convenience of use. If you are doing electrical work on your home, you can use either or a combination of both.

Single vs. Multi-Conductor Cables

The two most common types of single conductor wires are THW and THWN/THHN, which are protected by metal or plastic sheathing. The wires themselves can be either solid or stranded. Solid-core wire produces the best connections, but its stiffness makes it more difficult than stranded wire to route through conduit.

You can purchase wire by the foot or in spools that range from 50 to 500 feet. Depending on your installation, make sure to check the rating for indoor or outdoor application as well as for temperature tolerance.

The most common multi-conductor cable is made from metal or plastic and contains a neutral wire, a “hot” wire (or two), and a grounding wire. The neutral and hot wires are insulated by a thermoplastic material; the grounding wire may or may not be insulated. The wires are color-coded to guard against connection errors. Neutral wires are white or gray, grounding wires are green, and hot wires are any other color.

The cables shown here include: Two kinds of type NM cable, described above, which are the common choices for interior installations. The most recent version, known as NM-B, can only be used in dry locations and tolerates heat up to 140 degrees F.

NM and NM-B cable can be purchased by the foot and also come in boxes that hold anywhere from 25 to 250 feet of it. A larger version of NM cable, called large appliance cable, is sheathed in black, and because of its bulk contains stranded rather than solid wire to make routing it easier. Type MC armored cable is sheathed in spiral metal, but because of its expense it is not commonly used for interior applications.

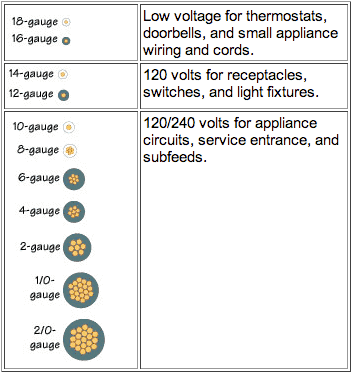

The various types of cable are also designated by how many conductors they contain and their size. For example, a cable identified as “14-2” with ground has one neutral and one hot wire as well as a grounding wire. The #14, designated by the American Wire Gauge, stands for the diameter of the wires alone, without insulation. The larger the diameter, the greater the wire’s capacity is to carry current. A conductor’s designation is stamped on the cable sheathing as well as on each wire.

The mostly commonly used metal for wires is copper, due to its efficiency as a conductor. Wire also comes in aluminum and aluminum clad with copper, but, because these are not as efficient in conducting current, the wires need to be larger to achieve the same capacity.

Before using either of these alternatives, check local codes.

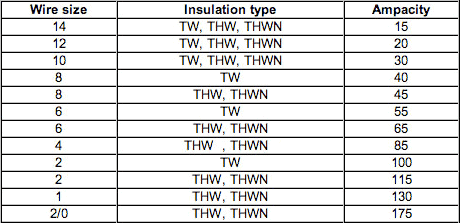

Allowable Ampacity

The allowable ampacity of insulated copper conductors by the wire size and insulation type

The following restrictions, from the National Electrical Code, apply when there are no more than three current-carrying conductors in a cable or enclosure.

Cross Sections of Copper Wires & Conductors

Armored Electrical Cable

Flexible armored electrical cable snakes through walls, floors and ceilings to provide a protective full metal jacket for wires.

Galvanized-steel spiral metal conduit was once the traditional material for wiring electricity in many houses but, since the invention and acceptance of nonmetallic cable, is now used mostly in situations where extra protection is needed for wires.

Two or three insulated wires run through each armored casing, and each wire is wrapped with rugged paper, called bushing. In a two-wire cable, one wire is black, the other, white. They’re color-coded to maintain continuity throughout the electrical system (the black is normally “hot” and the white is “neutral”).

The metal casing serves as a ground, but armored cable also has an internal ground or “bonding strip” that must run uninterrupted between all connections. The steel jacket may be cut with a hacksaw or bent and snipped with diagonals and then broken. Special connectors with bushings at the ends are for making connections to electrical boxes.

Armored cable, which dates back to the early 1900s, is commonly known as BX, a product designation it was given by its first makers, Johnson and Greenfield (the metal sheath without interior wires is called Greenfield). Today, where allowed by codes, BX may only be installed in dry, indoor locations. Romex nonmetallic cable has replaced BX as the most common type of home wiring.

Protecting Wires and Cables with Conduit

Conduit looks like plumbing pipe and serves to protect conductors from damage caused by moisture or impact. Several different conduit options are available; you will want to assess a job’s particular needs to determine which type is right for it.

Thinwall metal conduit is usually chosen for areas where it will be exposed, such as garages or utility rooms. Type EMT, as it is commonly known, is used for applications that do not require a lot of bending to fit around obstructions. Though EMT can be bent, it is much easier to buy prebent pieces. EMT is sold in lengths up to 10 feet; diameters range from 1/2 inch to 2 inches. (For more information, see How to Install Thinwall Metal Conduit.)

Flexible metal conduit looks like armored cable, but it contains no conductors. Also called Greenfield, it is the conduit of choice for large appliances such as water heaters and for areas where routing EMT would be too difficult. It can be used in outdoor and indoor applications. Flexible metal conduit is sold by the foot or in spools of 25 or 100 feet. Diameters are 1/2, 3/4, and 1 inch. (For more information, see How to Install Flexible Metal Conduit.)

Rigid nonmetallic conduit, made from PVC plastic, is a lighter alternative to metallic conduit for interior use. Schedule 40 conduit is sold in lengths of 10 feet. It should not be confused with PVC plumbing pipe, and it should only be used with housing boxes made from PVC as opposed to the nonmetallic boxes used with cable. (For more information, see How to Install Rigid Nonmetallic Conduit.)

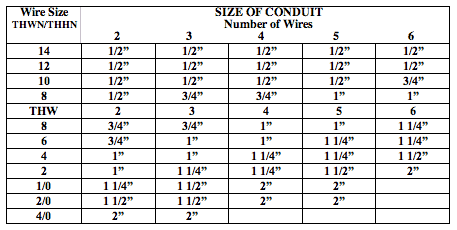

Assessing the application of the conduit, and the number and size of the wires it will accommodate, will determine the conduit diameter you will need. The chart above offers some guidelines.

Don Vandervort writes or edits every article at HomeTips. Don has:

Don Vandervort writes or edits every article at HomeTips. Don has: