Are your screens full of holes, sagging, or coming loose? Here’s how to solve these problems.

A hole or tear in the fabric of a window screen is all that it takes to let in persistent bugs. And, if a small hole or tear isn’t repaired promptly, it is bound to grow larger. Fortunately, you can repair holes and tears up to about 3 inches in diameter, and, when done properly, the patch will be barely visible. Holes larger than 3 inches generally call for replacing the screen fabric or the screen itself.

However, with regular maintenance, your screens can last for years. Remove and clean aluminum or fiberglass screens every year or so by gently scrubbing them with a medium-stiff bristle brush and a little soapy water, then rinsing with a hose. If you have galvanized metal screening that looks like it could rust, you can apply thinned screen enamel, paint, or varnish to them and paint the frames every few years. To remove oxidation from aluminum frames, clean them with steel wool and aluminum polish and coat them with a paste wax.

If your screens have wood frames, extend their life by reinforcing the corners with corrugated fasteners, wood screws, glued-in wood dowels, or metal reinforcing angles.

Replacing Window Screening

When window screens are torn, they allow bugs into your home. When they’re sagging or rusty, they look terrible and darken rooms. Fortunately, most screens are easy to remove and replace.

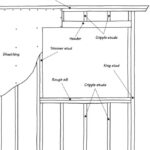

The frames will be either wood or metal, and the screens will be either metal (typically aluminum) or fiberglass. Chances are the frames themselves will not need attention nearly as often as the screens.

When cutting new metal screen fabric, be sure to wear gloves to protect your hands from sharp edges. Roll the screening out with the curved side down and mark your cutting line with a pencil along a straightedge. Cut metal screening with tin snips; vinyl screening with scissors or by laying the screening flat on a board and guiding a sharp utility knife along a straightedge.

1Pry out the vinyl splines that hold the fabric (use a screwdriver or chisel) and pull out the old screen fabric.

2Cut new fiberglass screen mesh large enough to extend to the frame’s edges.

3Using a spline roller, force the fabric into the empty channel along one side of the frame.

4Lock the fabric in place by pushing the spline back into the channel with the concave wheel of the roller.

5Pull the screen fabric taut and repeat along the other sides.

6Trim off the excess fabric using a utility knife.

How to Patch Window Screens

If you notice a small hole or tear in a screen, patching it before it grows larger will prevent you from having to replace it. You can buy any of several types of tapes and repair kits on Amazon—see these at the bottom of this page.

The methods that follow work for repairing slices or holes up to about 3 inches. For anything larger, replace the screen fabric or the entire screen.

Repair methods depend on the type of screening: Vinyl-coated fiberglass and metal (aluminum) are the two main types. Though they look similar from a distance, fiberglass screening is softer and more pliant, and metal screening, which is woven from tiny wires, is stronger.

A tiny hole in fiberglass screening is easy to fix. Just push the fibers back toward the center of the hole, daub the hole with clear nail polish, and allow to dry. This will weld the broken filaments together. To repair up-to-3-inch holes in both fiberglass and metal screens, you can buy self-adhesive pre-made patches for a few dollars or you can make your own from a small piece of like material.

To make your own patch, first cut a slightly larger patch from the same type of screening material, readily available at home improvement centers.

You can use household scissors to cut fiberglass screening; for aluminum or other metal screening, use tin snips and wear gloves to protect your hands from sharp edges.

To attach a fiberglass patch, use clear household repair cement. Thinly apply the cement around the perimeter of the patch to seal the edges, taking care not to create globs of glue.

To attach a metal screening patch, unravel the edges of the patch, bend the end wires at a right angle, push them through the screen fabric, and then bend them flat to hold the patch. Weave them into the fabric and then trim off any excess lengths of wire with diagonal cutting pliers.

Don Vandervort writes or edits every article at HomeTips. Don has:

Don Vandervort writes or edits every article at HomeTips. Don has: