Expert wood flooring buying guide helps you choose the best wood floor for your home, including types of wood flooring, quality, prefinished flooring, styles, trends, and more.

Are you in the market for new wood flooring? If so, this wood flooring buying guide will help you sort out your options.

Types of Wood Flooring

The type (“species”) of tree that wood comes from makes a big difference in hue and grain and in properties such as dimensional stability and hardness. You should also be aware of how the wood will respond to sanding, nailing, and finishing; some species have better “workability” than others.

The hardness of the wood helps determine how well your floor will stand up to wear and tear. Each wood species carries a hardness rating, known as a Janka rating—the higher the number, the harder the wood. Typical flooring hardwoods range from about 1320 (white ash) to 2820 (Brazilian cherry). The finish of your wood floor can also add significantly to its hardness.

Hardwoods, while usually harder than softwoods, are often more expensive and more difficult to install. The density of certain hardwoods can make for tough going when it comes time to saw, nail, and sand the strips or planks.

Another issue to consider is the dimensional stability of a wood species—how it responds to changing humidity conditions. This can be especially important if you live in an area with extreme fluctuations in humidity levels (such as hot, humid summers and cold, dry winters). Woods such as mahogany, cherry, teak, and walnut have good dimensional stability. Engineered-wood floors also offer greater dimensional stability than solid-wood floors because of their construction.

Following are certain characteristics of some of the most popular wood species available for hardwood floors:

White oak: A light-brown hardwood with an open grain and good durability and workability, white oak is heavy, weighing in at 47 pounds per cubic foot. It is very hard, with a specific gravity ranging from 0.57 to 0.81; its Janka rating is 1360. It is subject to considerable shrinkage, so seasoning must be done properly to avoid checking and warping.

Red oak: A reddish hardwood with a coarse, open grain and good durability and workability, red oak is similar to white oak, weighing in at about 44 pounds per cubic foot. Its specific gravity ranges from 0.52 to 0.60; its Janka rating is 1290. It, too, must be seasoned properly because of its proclivity to shrink. It is more porous than white oak.Maple: A whitish to light-reddish-brown hardwood with a closed, uniform grain, maple weighs about 44 pounds per cubic foot and has a specific gravity of 0.56. Because of its hardness, it can be difficult to saw and tool. It takes stain satisfactorily and can be given a high-polish finish. The wood’s Janka rating is 1450.

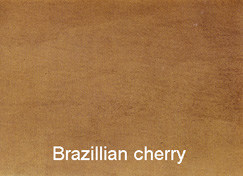

Brazilian cherry: An exotic hardwood with a reddish tone, an interlocking grain, and excellent hardness, Brazilian cherry is very popular for flooring because of its beauty, relative affordability, and, depending upon how it is grown and harvested, sustainability. It weighs about 55 pounds per cubic foot. Its Janka rating is 2820.White ash: A light-brown to dark-brown hardwood, white ash has an open grain and good workability. It weighs 42 pounds per cubic foot and has a specific gravity of 0.55. Its Janka rating is 1320.

Douglas fir: Though Douglas fir is not a hardwood and is not generally selected as new flooring, it is mentioned because some older homes have subflooring made of it. When sanded and refinished, these older floors can be beautiful. A light-brown to yellowish-brown softwood with a predominantly straight grain, it has good workability but should not be oversanded. It also can undergo a dramatic color change with sun exposure. Its Janka rating is 660.

Wood Flooring Quality

In addition to hardness, be sure to pay attention to the quality or “grade” of the wood product. The grade refers to the amount of manufactured and naturally occurring marks, characteristics, and variations allowed to appear in the wood flooring product. The National Wood Flooring Association (NWFA) has established a ratings scale to assist consumers.

A product with a NWFA “clear” rating will have a uniform appearance, while lesser grades will show more imperfections. Note that a higher grade does not always mean that a product will be better suited for your particular application, as you may, for example, desire a wood floor with more variation to achieve a certain design aesthetic, such as a rustic look.

Here are the four NWFA grades and what they mean:

Clear: A wood product made primarily from a species’ heartwood, the densest and oldest portion of a tree that often boasts a richer color than a species’ sapwood, located closer to the bark. A clear-grade product has very few character marks and very little discoloration, resulting in a mostly uniform look.

Select: Includes a mix of both heartwood and sapwood and, therefore, has subtle color variations. It can have a few natural wood characters showing through.

#1 Common: Features considerable color variations and a range of characters.

#2 Common: Shows obvious natural wood variation and characters, including knotholes as well as manufacturing marks.

Prefinished vs. Unfinished Wood Flooring

Today, most wood flooring sold, whether solid or engineered, comes with a polyurethane, aluminum oxide, acrylic-impregnated, or ceramic finish that protects the wood surface from wear and tear. Prefinished wood flooring saves consumers considerable time and effort, as the sanding, staining, and finishing tasks are completed before the product enters the home.

Unfinished wood flooring is still a viable option, however, particularly for those seeking to re-create a particular historical style or looking to match an existing hardwood floor. Because unfinished wood flooring is sanded down on site during installation and features strips or planks with square edges that butt seamlessly together, it can also have a more even, uniform look than prefinished flooring, which usually features edges beveled at a slight angle to help compensate for potential irregularities between flooring pieces.

Sustainable Wood Flooring Options

In its simplest terms, sustainability as it relates to forestry can be thought of as managing land and harvesting wood judiciously so as not to deplete resources, ecosystems, and local economies. A sustainable wood flooring product should offer durability and a long lifespan, ensuring that homeowners will not have to waste resources replacing a floor on a regular basis. Also factored into the equation is using local wood products, thereby reducing the carbon emissions generated by shipping a distance away from the end consumer.

If sustainability is an issue that concerns you, here are several options to consider:

Wood flooring certified by the Forest Stewardship Council (FSC): There are many agencies offering certification for wood flooring products, but the FSC is considered by many environmental organizations to have the most stringent standards for ensuring that wood comes from forests managed in environmentally and socially responsible ways. Be aware that manufacturers can boast of having FSC Chain of Custody certification, but this only means that they have the right to carry FSC-certified products—it does not actually mean that they do. You must inquire as to whether the specific flooring product you are interested in carries the certification and request documentation if you are at all unsure.

Bamboo: Bamboo is a highly renewable flooring resource because the bamboo plant (technically a grass) reaches maturity in considerably less time than most of the trees used to make wood floors; requires less water to produce a mature crop; and grows in groves that are easy to manage throughout the planting, tending, and harvesting cycle. Harvesting bamboo also does not kill the plant. (For more information, see Bamboo Flooring.)

But do your research—some bamboo flooring comes from bamboo plantations that have displaced natural forests in China or other regions of Asia, where most of today’s bamboo is grown. The fact that the product is grown abroad also means that a considerable amount of energy is consumed shipping the product.

Eucalyptus: Eucalyptus is gaining popularity as a “green” hardwood because the tree grows rapidly and reaches maturity faster than most other species. The Weyerhaeuser Co.’s Lyptus solid- and engineered-wood flooring products are made from hybrid eucalyptus trees grown on South American plantations. There are also manufacturers offering eucalyptus grown in well-managed European forests.

Reclaimed & Salvaged Wood Flooring

Homeowners who have environmental concerns about installing wood floors but like the beauty of oak, maple, and pine now have options due to a relatively new industry that is quickly gaining traction. Reclaimed and recovered wood floors are now available in almost every market in the United States and can provide a second or even third life for timber.

Salvaged wood can come from a surprising number of sources. While old barns have traditionally been a reliable source for reclaimed wood, this resource is becoming scarce. But, as demand for reclaimed wood has risen, companies have started to find other sources for the material and expanded the definition of reclaimed wood.

Today, industrial buildings slated for demolition, condemned structures, and even bowling alleys provide an increasing amount of reclaimed wood for the home improvement market.

Wood pulled from the bottoms of creeks and rivers is another source for flooring. In the past, logging operations often floated timber down rivers and creeks to be milled. During the process, a certain percentage of the timber would sink to the bottom. Until just recently, salvaging this wood was too expensive, but, as the demand for reclaimed and recovered wood has risen, some companies are now plumbing the depths for these sunken treasures.

Recovered timber from forest fires can also be salvaged and milled for flooring. Often this wood is stained or marked by the intense heat of the fire, giving it a unique look.

Though sometimes twice the cost of traditionally milled hardwood floors, reclaimed wood floors combine an aesthetic quality with environmental responsibility. Black walnut, cypress, redwood, cherry, and even the now-extinct American chestnut can be sourced, as can traditional oak, pine, and maple.

The look and feel of reclaimed and recovered wood is often varied and irregular, with natural knots, worm holes, saw marks, and color variations. Newer recovered wood can be scraped and stained (distressed) to create an antiqued look.

Whenever possible, reclaimed wood is milled into wide planks to highlight the age and feel of the wood. Though some reclaimed wood has tongue-and-groove edges, most often installation is slat style. Rough edges and gaps in the flooring between planks is to be expected (if not encouraged) to enhance the authentic appearance.

The SCS has created the “100% SALVAGED WOOD from Recovered Submerged Timber” designation. SmartWood is another third-party certification body that evaluates forest product operations that are reclaiming, recycling, and/or salvaging wood materials.

Find a Pre-Screened Local Wood Flooring Contractor

Wood Flooring Styles & Trends

Once you have considered your new wood floor’s structural aspects, you can explore myriad design options. While strip flooring, made up of strips up to 3 1/4 inches wide, can make a room look large and formal, plank flooring, made up of planks more than 3 inches wide, is becoming increasing popular.

You can pick a floor showcasing the natural color of your selected wood species or choose a stained look, which can offer a hard-to-find hue or a uniform appearance.

Finally, hand-scraped wood floors, which feature a textured, distressed surface, are a lovely, unique option with an Old World feel.

Whichever variety of wood flooring you decide upon, be sure to investigate the manufacturer’s warranties guaranteeing the product’s finish and structural qualities.

Bamboo Flooring

Bamboo flooring is a hard, stable, and reliable flooring material with a pleasingly exotic appearance. It has several unique qualities. For one, it has exceptional pliability that allows it to sustain blunt impacts without denting or bending—in this attribute it surpasses most hardwood materials. In addition to its superior elasticity, bamboo is surprisingly hard. It has a Janka rating of about 1800, which is considerably harder than that of white oak (1360) and maple (1450).

Because bamboo grows in tropical regions, it has an organic resistance to water. But it does expand and contract with changes in its moisture content, and it can stain. If you’re going to use bamboo in a bathroom or a kitchen, it may be wise to apply an extra coat of polyurethane or wax following installation to ensure a permanently flush and stain-free surface. Check with the flooring manufacturer and/or your installer for the right products to use.

As with regular wood floors, bamboo flooring comes in solid and engineered tongue-and-groove strips and planks, which means there are bamboo options available for both plywood and concrete subfloors. Because of the thinness of the bamboo stalks, solid-bamboo flooring is actually composed of bamboo strips that have been laminated together. Engineered-bamboo flooring has a veneer of bamboo over layers of plywood. There are also “click-together” varieties that are assembled simply by snapping flooring pieces together, but be forewarned that these often do not bear as professional a look once they are installed.

Although bamboo is naturally light in color, it can be darkened by steam and pressure in a process called carbonization. (Be aware that carbonization is said to soften bamboo by as much as 30 percent, resulting in a flooring product that may be less resilient.) Some manufacturers also offer a range of stained bamboo flooring, as well as hand-scraped options.

While bamboo flooring is now widely available, not all bamboo is created equal. Low-cost bamboo is generally made from stalks that have yet to fully mature, which means the plant has not developed the density needed to make an acceptable floor and will easily mar and dent.

Because bamboo is a type of grass that renews every few years, it is considered an environmentally friendly product. (For more on this, see Sustainable Wood Flooring Options.)

NEXT SEE: Solid or Engineered Wood Flooring

Featured Resource: Find a Pre-Screened Local Flooring Pro

Don Vandervort writes or edits every article at HomeTips. Don has:

Don Vandervort writes or edits every article at HomeTips. Don has: