Free plans, diagrams, and step-by-step instructions for building a simple 4-by-6-foot outdoor shed. Get those garden tools organized!

Tools and Materials List

| Tools | Basic carpentry tools such as:

|

| Materials | • Pressure-treated 4x4s for the foundation • Pressure-treated 2x4s for floor joists • 3/4″ Tongue-and-groove plywood for flooring • 2x4s For studs, header, rafters, top plate nailers, etc. • T1-11 Plywood siding • 1/2″ CDX plywood for roof sheathing • 1×3 Door trim • 1×4 Fascia and rake trim • Asphalt shingle roofing, 15-pound felt, metal framing brackets, door hinges and latch, miscellaneous galvanized nails and outdoor screws, and paint, stain, or preservative. |

Have you been longing for a shed where you can store lawn and garden equipment, sports equipment, compact outdoor furniture, and miscellaneous tools and supplies? When inconspicuous, functional storage is all you’re looking for, a lean-to shed is the perfect solution.

Per its name, the structure simply “leans” on the house or garage for additional support and provides a water-safe haven for shielding gear from the elements. If you have moderate do-it-yourself skills and tools, this is a 2-weekend project. If you decide it’s more than you bargained for, check out these convenient lean-to shed kits on Amazon.

Browse Tools for This Project on Amazon

• Combination Squares

• Power Circular Saws

• 4-Foot Levels

• 16-Foot Tape Measures

• Framing Nailers

• Pancake Air Compressors

Storage Shed Design

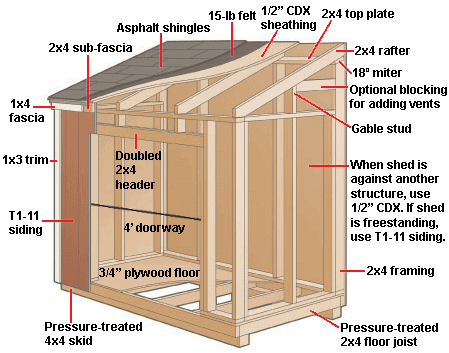

The foundation of the shed is simply designed from pressure-treated lumber. In addition, the roof is pitched in only one direction to shed water, and the back wall is sheathed with 1/2-inch CDX plywood, which withstands indirect exposure to moisture. See Anatomy of an Outdoor Shed or Playhouse for more about typical shed construction.

Plan Modifications

It isn’t a requirement that this shed be built against a wall—but the structure is designed to take advantage of the wall for strength. So if you modify it to be a freestanding shed, you’ll need to build a conventional stud wall across the back and face it with the same type of plywood siding used on the rest of the shed. For information on how to mark, cut, and fasten wall studs, see How to Frame an Interior Wall (ignore the part about working with drywall because you’ll be using exterior-rated T1-11 siding instead).

For a freestanding shed, you can build the shed on top of a concrete slab (see Pouring a Concrete Slab) instead of the pressure-treated skids and floor joists; this will actually result in a sturdier—more permanent— structure. Otherwise, for a freestanding shed, the foundation should be constructed on concrete piers or poured footings (see Pouring Concrete Footings & Piers). Be aware that building on footings will raise the height of the shed up from the ground.

Materials Required

To build the shed shown here, you’ll need:

• Pressure-treated 4x4s for the foundation

• Pressure-treated 2x4s for floor joists

• 3/4″ Tongue-and-groove plywood for flooring

• 2x4s For studs, header, rafters, top plate nailers, etc.

• T1-11 Plywood siding

• 1/2″ CDX plywood for roof sheathing

• 1×3 Door trim

• 1×4 Fascia and rake trim

• Asphalt shingle roofing, 15-pound felt, metal framing brackets, door hinges and latch, miscellaneous galvanized nails and outdoor screws, and paint, stain, or preservative.

Building the Shed

The shed shown here is 6 feet long by 4 feet wide. You can easily expand its dimensions in increments of 2 or 4 feet.

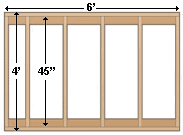

1 To construct the framing for the shed’s floor, cut two pressure-treated 2 by 4s to a length of 6 feet for the rim joists. Then position six 45-inch-long floor joists between the rim joists 16 inches on center (with the exception of the last one, as shown in the floor joist detail at right). Attach them with 16d nails.

Cut two pressure-treated 4 by 4s to a length of 6 feet for the skids. Position the frame on the skids, and, when square, toenail the floor joists to the skids.

Attach 3/4-inch tongue-and-groove plywood flooring onto the frame.

2 The walls for the shed are constructed separately and then raised onto the frame.

Start with the back wall, which is 8 feet high with 6-foot-long top and bottom plates and four studs placed 18 inches on center. The tops of the wall studs are mitered at 18 degrees. Attach the wall to the floor frame and temporarily brace it.

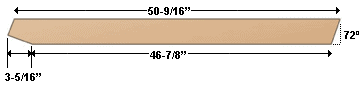

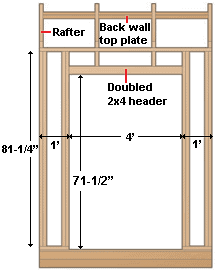

The front wall has a 6-foot-long top plate and two 1-foot-long bottom plates, leaving space for a 4-foot-wide door. The four wall studs are 81 1/4 inches long; install them as shown in the front framing detail at left. Next, install the 73-inch-long jack studs, and then attach the 51-inch-long doubled header. Finally, attach the 6 1/4-inch-long cripple studs.

Raise the front wall, attach it to the floor, and temporarily brace it.

The side walls have top and bottom plates 41 inches long and studs 81 1/4 inches tall. Raise them, attach them to the floor, and temporarily brace them if needed. When all wall sections are square, attach them at the corners with screws.

3 The frame of the roof consists of four 2-by-4 rafters cut so that they rest on the front- and rear-wall top plates, as shown in the rafter detail at right. Install a gable stud directly over the center studs on both side walls to fit between the end rafter and the top plate. Install the sub-fascia and then the fascia to the front ends of the rafters.

4 Position pieces of T1-11 siding on the front and sides of the shed so that they are flush with the bottom of the rim joists. Attach the siding with 8d galvanized nails spaced every 8 inches.

Cover the rear wall with 1/2-inch CDX plywood from the bottom of the rim joists to the tops of the rafter ends.

5 Sheath the rafters with 1/2-inch CDX plywood; stagger the joints so that none end up on a rafter. Nail them in place with 6d nails. Attach rake trim to cover the exposed edges of the roof sheathing, and install drip edging. Roll out 15-pound roofing felt, and apply the shingles (see Asphalt Roof Installation).

6 Construct the doors from T1-11 siding, and trim them out with 1 by 3s. Add cross trim in the centers of both doors, and install the door latches. Use strap hinges to attach the doors.

Featured Resource: Find a Pre-Screened Local Shed Builder

NEXT SEE:

• Anatomy of an Outdoor Shed or Playhouse

• Building a Shed or Playhouse

• Fastening a Patio Roof to the House

• How to Build a Horse Barn

How to Build a Lean-To Shed FAQs

- What is the cheapest way to build a shed?

The cheapest way is to construct a lean-to shed that takes advantage of a house wall for part of its support and enclosure. Doing the work yourself can save more than half the cost.

- What are the disadvantages of a lean-to shed?

Lean-to sheds offer limited space, must be located at a house wall, may have structural weaknesses if not properly attached to the wall, and can cause water drainage issues at the supporting wall.

- How much does it cost to build a lean-to shed?

A lean-to shed can cost between $500 and $5000+, depending on its size, the quality and type of materials, and whether you build it yourself or hire professionals.

Don Vandervort writes or edits every article at HomeTips. Don has:

Don Vandervort writes or edits every article at HomeTips. Don has: